Products

Natural gypsum powder production line

Category:

Natural gypsum powder production line

规格:

食用方式:

特点:

Keyword:

Natural gypsum powder production line

Natural gypsum

Emial:

lyhuihang@sina.com

Description

Parameters

Utilize natural gypsum as raw material

Production: 10,000 tons to 800,000 tons per year

1. Brief description of the production process:

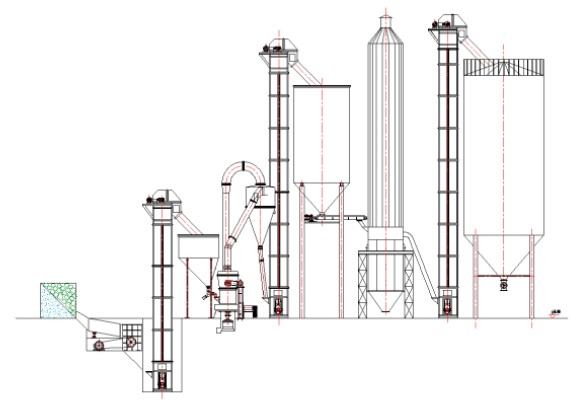

The crusher crushes the large-sized gypsum ore into small pieces smaller than 25mm, which are stored and controlled by the electric vibrating machine and sent to the mill for grinding. The qualified gypsum raw powder is sent to the boiling furnace for calcination. The qualified gypsum powder after calcination is sent to the clinker silo for storage.

2. System structure:

According to the process requirements, the production line is divided into four parts: crushing part, grinding part, boiling furnace calcining part and finished powder storage and packaging and conveying part.

System structure features:

a. Advanced technology, mature and stable technology, widely used in gypsum board production lines at home and abroad

b. The selected equipment is of reliable quality, with strong expansion and overproduction capacity; low maintenance and convenient maintenance.

c. Good sealing, efficient dust removal, no dust pollution.

d. The fully integrated automatic control system reduces the on-site staff and labor intensity.

3. Electrical control system:

The electrical control system adopts the current advanced DCS (distributed control system), which centrally controls the equipment scattered in various places.

4. The process flow is as follows:

With the development and progress of the gypsum industry, the demand for gypsum powder in all walks of life is also increasing, and the quality requirements for gypsum powder are also getting higher and higher. The production and manufacturing process of gypsum powder is also constantly improving. Drying and dehydration is the key link in the production and processing link, and it is also the part that is difficult to grasp. According to this situation, we have developed a new generation of gypsum powder production requirements based on the continuous exploration and research of gypsum powder production and deep processing industry for many years. Dehydration equipment - boiling furnace.

1. The main working principle of the boiling furnace drying system: the main body of the boiling furnace is mainly composed of small-diameter and dense heat dissipation coils. The heat-conducting oil is passed into the coils, and after heat exchange, the heat is released into the furnace body. A Roots blower is installed at the bottom of the boiling furnace, and the cold air is blown into the furnace body through the air distribution plate to blow the powder in the furnace body. The material reaches the boiling state. At a certain temperature, the powder that has been dried to remove the water of crystallization will automatically flow to the discharge port after the weight becomes lighter. In this way, the quality of the gypsum powder produced is stable, the content of crystallization water, the initial and final setting time easier to control. In addition, after the equipment uses a high-efficiency dust collector to remove dust, the dust removal efficiency reaches more than 98%, eliminating dust pollution.

2. Simple structure, not easy to damage

Since the material is fluidized, the furnace does not need to have rotating parts, and the structure of the furnace is much simpler. Not only is it convenient to manufacture, but it also requires almost no maintenance after it is put into production. Due to the low temperature heat source, the furnace is not in danger of being burnt out under any circumstances, and the service life of the equipment is particularly long.

3. The equipment is compact and occupies less space. The boiling furnace is a vertically arranged equipment. The dust collector is placed on the top of the furnace body and is connected to the furnace as a whole. The equipment is very compact. Not only does it occupy less space, but it can also avoid condensation on the dust collector.

Next

None

Message

客户留言

Description:

Contact Us

Scan QR code

Mobile version

Message

客户留言

Description:

Copyright © Linyi Huihang Machinery Co., Ltd. 鲁ICP备13029513号 Powered by www.300.cn SEO